Bright-line vibration and noise criteria

If you’re outfitting a low-vibration imaging suite or laboratory, you’ve probably had to read a few tool installation guides for off-the-shelf (as opposed to hand-built) instruments. These documents are provided by instrument vendors and provide some environmental guidelines for parameters like floor vibration, acoustical noise, EMI, temperature, humidity, and more. Often, the vendor will withhold sales to sites that don’t or can’t meet these environmental criteria, since performance cannot be guaranteed under adverse conditions.

One problem with floor vibration criteria for laboratory instruments is that—unless we helped develop the criterion—we never get to see an “error-vs-vibration” dataset. The same goes for acoustical noise, as well. Researchers as well as vibration consultants are generally not given anything more than a simple bright-line (PASS/FAIL) criterion.

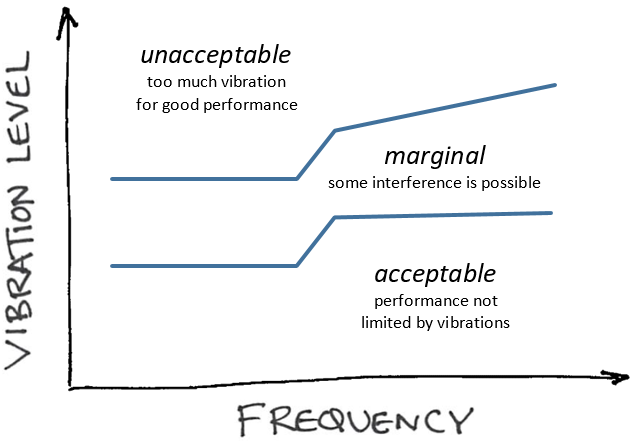

The criteria often acknowledge that there is some frequency dependency: the limit is provided as a spectrum, since the tool might be more or less sensitive to lower or higher frequencies. Occasionally, a vendor will provide a multi-tiered criterion: unacceptable, generally acceptable, and a “marginal” region between the two, in which some (possibly-tolerable) vibration interference might occur:

A multi-tiered criterion can be very useful, because it allows potential customers and their consultants to engage in at least a little bit of cost-benefit analysis: should we invest in a quieter environment, or accept occasional interference?

The actual vibration sensitivity is of course far more complex: the spectra in the criterion are surely envelopes of a considerably more-intricate shape, and in reality there is a continuum of degrees of interference. Significantly, there is also diversity in the customer base: one lab group might want to use the tool in a way that makes it more-or-less-sensitive than is typical. That diversity is one of the reasons that conservatism has to be built into the statement.

I believe that there is a way to reduce that conservatism, or at least generate more-accurate criteria. One of the reasons why bright-line criteria are written is that both vendors and customers have to assume the worst when it comes to the temporal distribution of building vibration levels as compared to the timescale of tool sensitivities and operations. If toolmakers could somehow introduce a temporal or statistical component to their criteria, then vibration consultants might be able to help their clients make better purchasing decisions.

I know it wouldn’t be easy, but I think that smarter criteria would boost sales for toolmakers, since restrictions could actually be relaxed for some potential customers. Imagine two candidate laboratory instruments that are competitive in terms of cost and performance, but differ in floor vibration criteria:

Tool X: “meet the VC-F criterion (1.6um/sec in 1/3 octave bands from 1 through 80Hz)”

Tool Y: “for long pre-programmed scans, meet VC-F (1.6um/sec) in at least 50% of 30-second time periods; for short, attended scans, meet the VC-D criterion (6.3um/sec) in at least 80% of 1-minute time periods”

All other things equal, Tool Y is immediately more attractive: VC-F in 50% of 30-second time periods is easier to meet than VC-F all the time. And knowing that there is an even less-restrictive tier for certain uses might mean that research groups that only do short scans would find it far easier to buy and install Tool Y.

Again, I’m not entirely sure how easily one might construct these criteria, or whether they would even be useful for all vendors. However, it seems likely that criteria are occasionally overly-conservative because the toolmaker can’t differentiate between (1) different temporal vibration environments; and (2) different use cases that affect the timescale of sensitivities.

Contact us if you need help developing or working with environmental criteria for modern lab buildings, whether for an off-the-shelf instrument or for a one-of-a-kind installation. We have consulting experience with toolmakers as well as research institutions, and we can help make your product or project more successful.